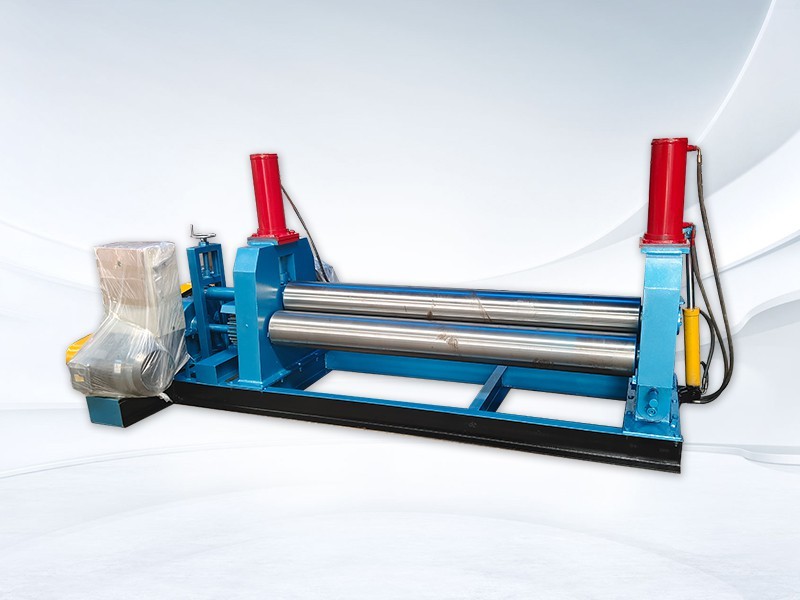

3 roller cone rolling machine is a mechanical equipment used to process sheet metal into a conical shape.It mainly consists of three roller shafts,which rotate and cooperate with each other to achieve the rolling operation of the sheet,gradually deforming the sheet into the required conical shape.For example,in some metal processing industries,components used to manufacture conical containers,etc.

1.Structural design:The three rollers of the

3 roller cone rolling machine are equipped with a pair of conical roller bearings in the radial direction,which enables them to withstand both radial and axial forces during the rolling process,making the rolling process smoother and lighter,and avoiding the problems of the rollers spinning at the original position of the pipe and stopping during the rolling process in traditional methods.

2.Transmission system:The transmission system of the 3 roller cone rolling machine press adopts a high-speed shaft design and is equipped with a centrifugal friction clutch,which can effectively reduce the starting torque and dynamic load of the transmission components,making it easy to start and reliable to operate.

3.Execution mechanism:The adjustment of the rolling head is carried out through a screw,which can infinitely adjust the helix angle,making the rolling process more flexible.

4.Scope of use:The 3 roller cone rolling machine is suitable for threaded pipes with diameters ranging from 38-76 millimeters,with a large lead range(20-240 millimeters).It can roll threaded pipes of different diameters and any pitch,and even roll multi head threaded pipes with large lead.

5.Operational flexibility:The position of the rolling head and three claws can be exchanged.When the rolling head rotates but the workpiece does not rotate,the length of the threaded pipe that can be processed is not limited,which is incomparable to other processing methods.

6.Maintenance and upkeep:Due to the unique working principle of the 3 roller cone rolling machine,most of the time maintenance and upkeep require professional technicians to operate,resulting in relatively high maintenance costs.

With the continuous advancement of industrial technology,the demand for 3 roller cone rolling machines in the market continues to grow.Especially in fields that require high processing efficiency and accuracy,the application of such machines is becoming increasingly widespread.At the same time,with the development of automation and intelligent technology,future 3 roller cone rolling machines will be more intelligent and able to better adapt to complex and changing production needs.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com