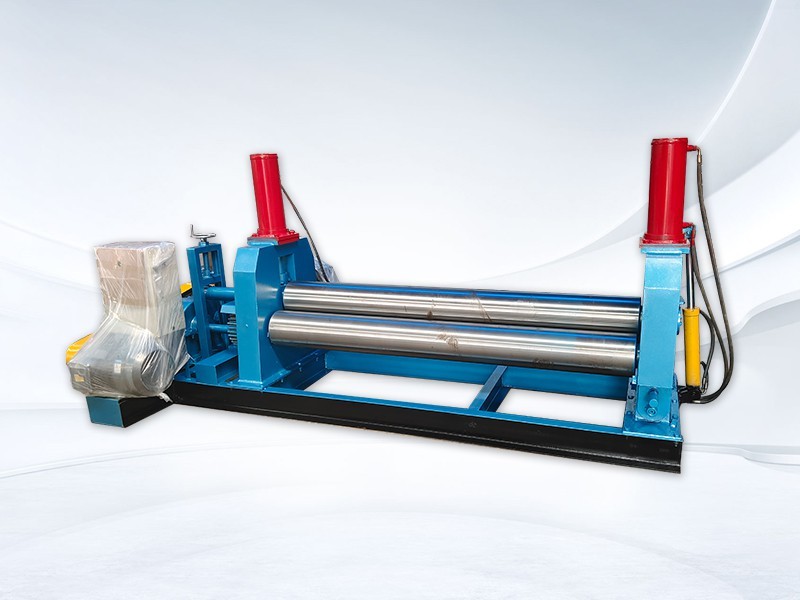

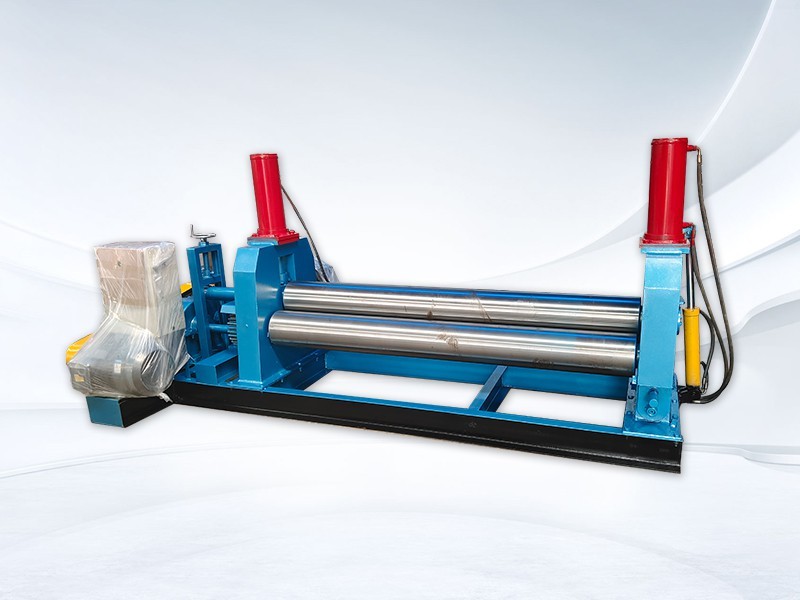

A three roll cone rolling mill is an equipment used for metal processing,mainly composed of usually used for rolling steel sections and plates.The working principle of

3 roller cone rolling machine manufacturer is to achieve plastic deformation of the metal material through the interaction of the three rolling rolls to achieve the desired size and shape.Specifically:

1.Transmission method:The upper and lower rollers are driven by a motor,while the middle roller is driven by the friction between the upper and lower rollers.

2.Rolling process:The rolled piece is first rolled between the lower and middle rolls,then lifted and reversed by a lifting platform,and then rolled between the middle and upper rolls.This process is repeated until the thickness required by the 3 roller cone rolling machine manufacturer is reached.

The 3-roll cone rolling mill is relatively simple,with low construction and maintenance costs.Due to the high stiffness of the rolling mill rolls,the precision of the produced steel plates or profiles is high,making it suitable for producing various metal materials such as medium plates and wire rods.It is widely used in metal processing industries such as steel and non-ferrous metals.It is suitable for producing various metal materials such as medium plates and wires,especially performing well in the production of medium plates ranging from 4.0 to 20mm.In addition,the 3-roll cone rolling mill can also be used as a roughing mill in a dual machine arrangement,further improving production efficiency and product quality.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com