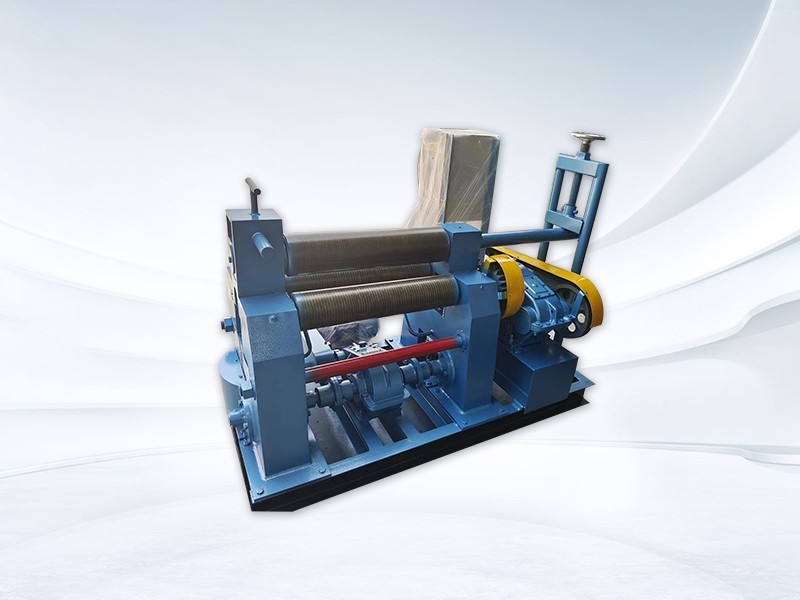

The process flow of a two roll plate rolling machine includes preliminary preparation, operational steps, and post-processing.Below, the 2 roll plate rolling machine manufacturer will introduce the detailed content:

Firstly, sufficient preliminary preparation work is required before operating the rolling machine. This includes inspecting and maintaining the rolling machine to ensure its normal operation. At the same time, it is necessary to adjust the spacing and pressure of the rollers to meet the processing requirements of different materials.

After the preparation work is completed, we enter the operational step stage. Firstly, place the material to be processed at the feeding position of the two roll plate rolling machine, and adjust the positions of the feeding wheel and the carrying roller as required. Next, by starting the rolling machine, the material is fed into the rolling area. During the rolling process, the rotation of the roller shaft bends the material and enters the working area, causing it to gradually roll up under the pressure of the roller.

In order to ensure processing quality, operators need to adjust the spacing and pressure of the rollers in a timely manner according to the properties and requirements of the material, to ensure the flatness and shape of the material. During the rolling process, operators also need to pay attention to the coordination of material feeding speed and winding speed, to avoid situations where the material is too fast or too slow, so as not to affect the quality of the rolling.

After completing the rolling process, we enter the post-processing stage. Firstly, remove the coiled sheet from the two roll bending machine and conduct necessary inspections. For coils that do not meet the requirements, they need to be repaired or disposed of. For qualified coils, the next step of processing or subsequent work such as delivery can be carried out.

In summary, the process flow of a two roll plate rolling machine includes preliminary preparation, operational steps, and post-processing. By carrying out reasonable preparation work and executing operational steps, the normal operation of the rolling machine and the stability of the processing effect can be ensured, thereby improving production efficiency and product quality.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com