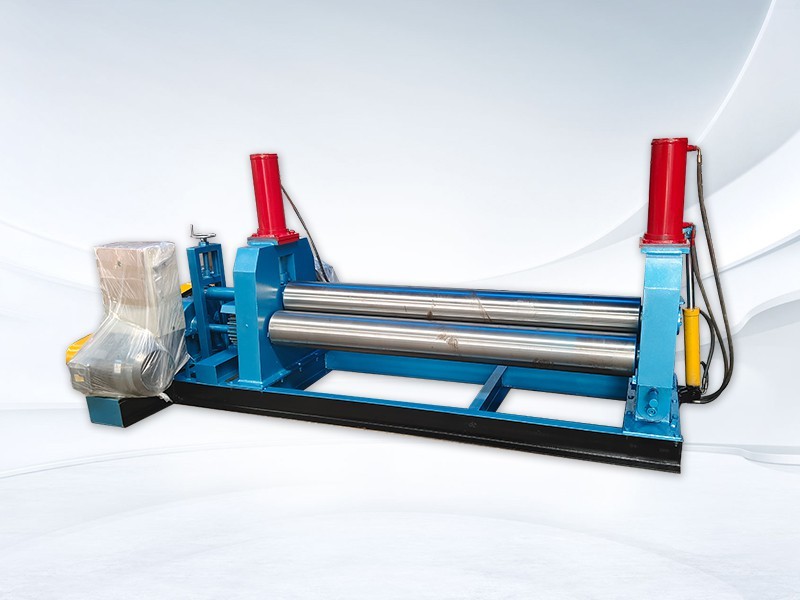

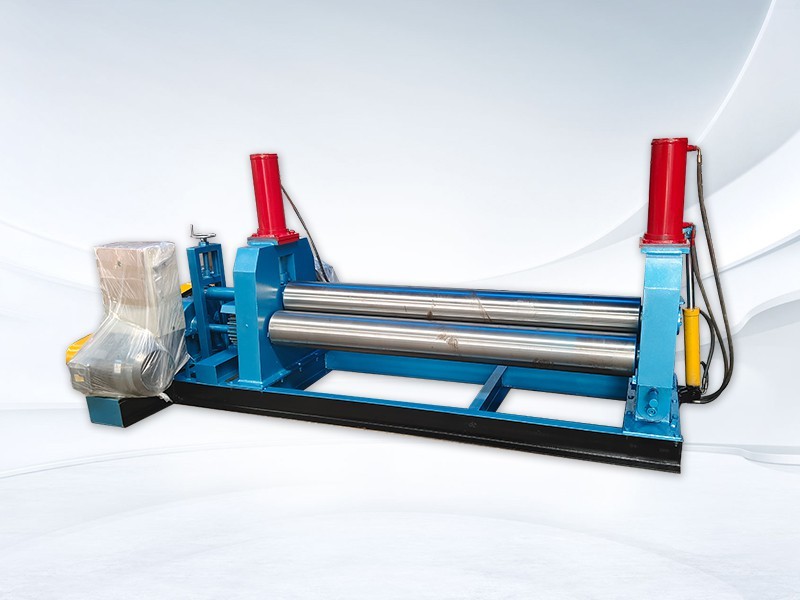

The working principle of the

three roll cone bending machine is to roll and bend metal sheets into conical or other specific shaped workpieces through the collaborative action of three working rolls.Specifically,the working principle of the three roll cone bending machine is based on the principle of three-point rounding.Through changes in the relative position and rotational motion of the workpiece,the sheet undergoes continuous plastic deformation,thereby obtaining a predetermined shape of the workpiece.

1.The lifting motion of the upper roller:The upper roller is located at a symmetrical position in the center of the two lower rollers,and the vertical lifting motion of theThree roll cone bending machine is achieved by the hydraulic oil in the hydraulic cylinder acting on the piston.

2.Rotation of the lower roller:The lower roller is driven by the final gear of the main reducer to rotate and provide torque for the rolled sheet.

3.Bending processing of sheet metal:Flat plastic metal sheets are subjected to multiple continuous bending passes through three working rollers,with the upper roller pressing down and the lower roller rotating,resulting in plastic deformation.The three roller cone bending machine rolls the sheet metal into the required conical or other conical workpieces.

The three roll cone bending machine,with its unique technical characteristics and wide application fields,plays an important role in industrial production and demonstrates enormous market potential and development prospects.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com