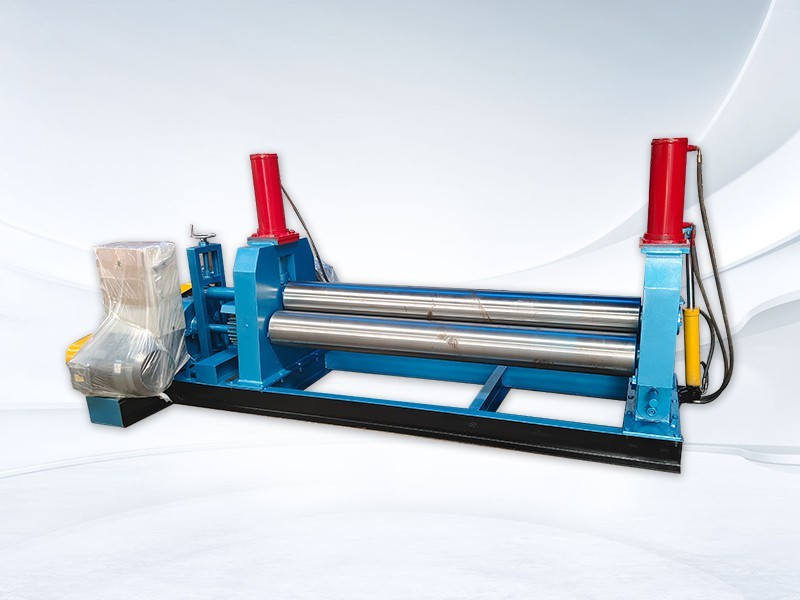

The three roll cone bending machine is a common metal forming equipment,mainly used for processing metal cones of various shapes.In order to ensure the normal operation and prolong the service life of the equipment,regular maintenance is very important.The specific maintenance measures for

China three roll cone bending machine bending machine are as follows:

1.Cleaning:After daily use,the China three roll cone bending machine should be cleaned,including the rollers,machine,interfaces,etc.,to ensure cleanliness,avoid the accumulation of dust and dirt,and affect the normal operation of the machine.

2.Add lubricant:It requires adding lubricant to lubricate all interfaces and mechanical components,ensuring reduced friction and smoother operation.

3.Check the rollers:Before each use,the wear level of the rollers should be checked.If the wear is severe,it should be replaced in a timely manner.At the same time,ensure that all rollers are installed correctly and there is no looseness or deviation.

4.Machine maintenance:Regularly inspect all components of the China three roll cone bending machine to ensure that they are in good condition.Check if the motor,wires,and cables are functioning properly,and promptly address any malfunctions.

When operating the China three roll cone bending machine,it is necessary to pay attention to standardized operation to prevent waste or misoperation from affecting the operation of the machine.Avoid using materials that are too small or too hard for processing,in order to avoid excessive wear and tear on the three roll machine.During the use of the three roll machine,avoid excessive load to prevent damage to the machine.Regular daily maintenance and upkeep should be carried out to ensure the normal operation of the machine and extend its service life.

By implementing the above maintenance measures and safety operating procedures,the service life of China three roll cone bending machine can be effectively extended,production efficiency can be improved,and the safety of operators can be ensured.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com