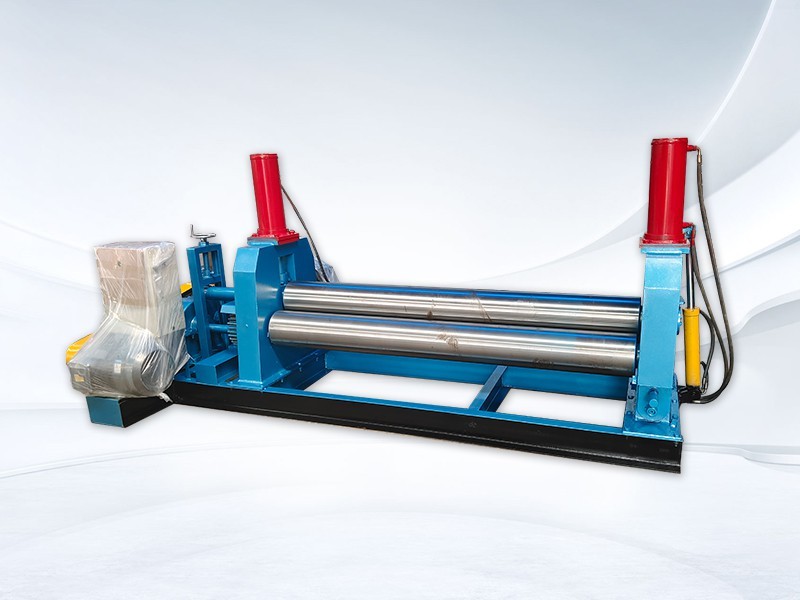

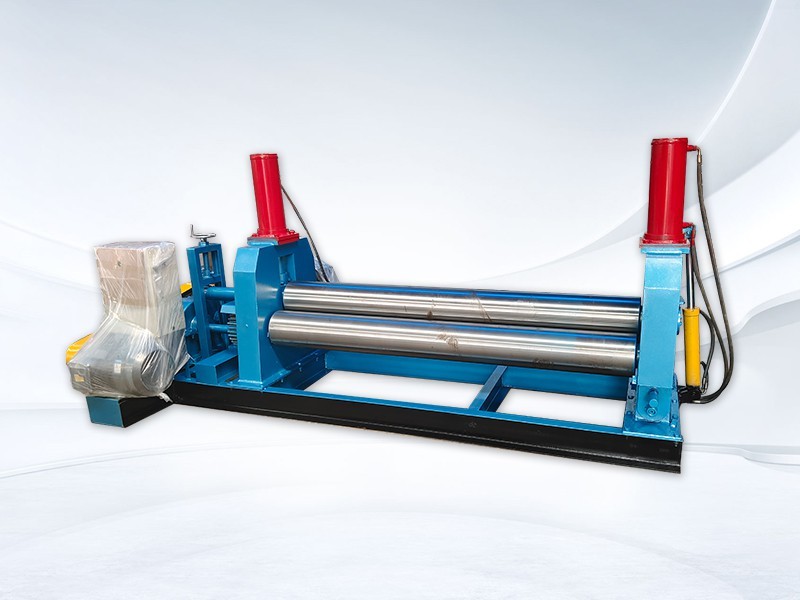

The three roll profile bending machine is an effective processing equipment,mainly used for bending various shaped steel materials such as angle steel,channel steel,I-beam,flat steel,square steel,round steel,etc.The working principle of the

three roll cone bending machine factory is to achieve the rolling of profiles through the main driving rollers of the three working rolls,combined with hydraulic motors and gears.The lifting of the two rollers adopts hydraulic transmission,which can perform curved lifting and lowering movements around the fixed rotation center,thereby ensuring the rolling quality of asymmetric cross-section profiles.

The manufacturer of the three roll cone bending machine adopts a steel plate welded structure and undergoes annealing treatment to eliminate internal stress,ensuring the overall strength and rigidity of the machine.It is installed in the cavity of the bed and achieves curved lifting motion through the edge roller oil cylinder.Installed on the left and right rotating arms,it can move in an arc with the edge rollers and achieve rotational and lifting movements through the rotating oil cylinder and lifting oil cylinder.

In summary,the three roll cone bending machine factory ,as an effective and sophisticated processing equipment,plays an important role in multiple fields.By understanding its working principle,structural characteristics,and application scope,it can help users make choices for manufacturers of three roll cone bending machines.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8615653328535

WhatsApp:+8615653328535 Wechat: +8615965331535

Wechat: +8615965331535  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com